Fully Automated Test Jig for Printed Circuit Board (PCB) Manufacturing

Benefits for the business as a result of delivering this solution include:

- Single device for all test requirements – incorporating PCB programming

- New UI for enhanced user experience and data insight

- Simplified calibration process, built into UI

- Configurable automated test sequence – future proofing and simplifying modifications

- No requirement for operator input, press start test, remove PCB and action depending on pass or fail

Background to the project

EnviroVent is one of the UK’s leading manufacturers of low energy, sustainable domestic ventilation equipment designed to create all year round, healthy, fresh and ideal indoor environments. They chose Argenta to deliver a series of test jigs for a new set of PCBs used in their products.

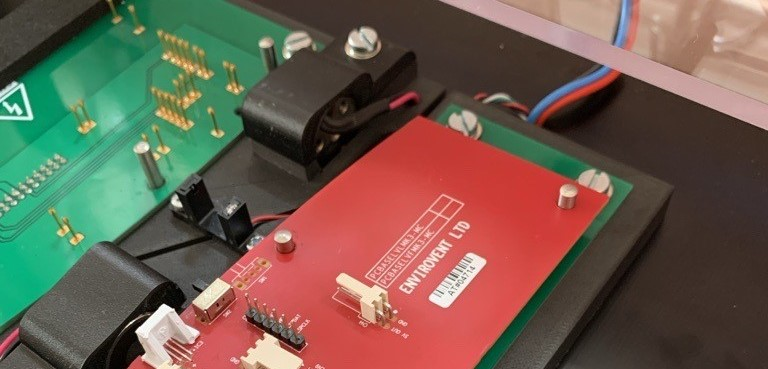

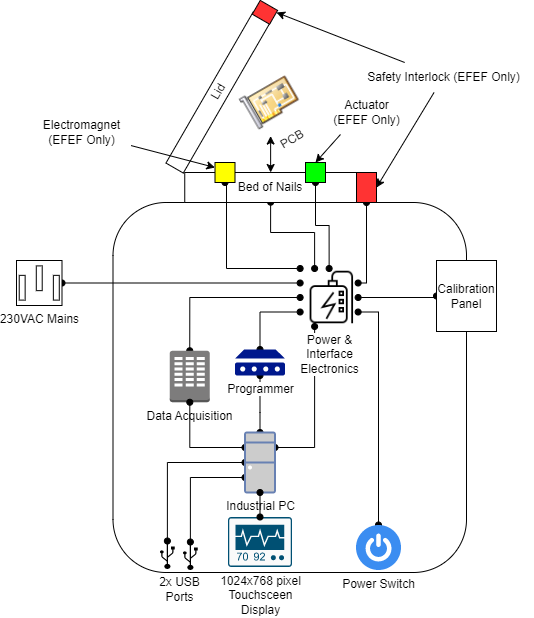

The jig design, see diagram to the right, incorporated several different test requirements to enable a comprehensive test sequence to be executed on the PCBs. There are 3 types of PCBs which were tested on 2 different jigs. As two of the PCBs were being tested on a single jig (at different times), the testing capacity was increased by having separate jigs for all three PCBs.

Solution in detail

Accuracy of measurements was a top priority so enabling flexible and easy to use calibration was high on the list. The Calibration panel provides the ability to connect laboratory calibrated sources to the jig and perform calibrations of the analogue signals being acquired and controlled using the data acquisition hardware.

It was important to make the jigs configurable so that we had a single software application for all 3 PCBs and the hardware for the jigs remained as consistent as possible. The configurability also means that tests can be set up and modified using a configuration file, further future proofing the jigs.

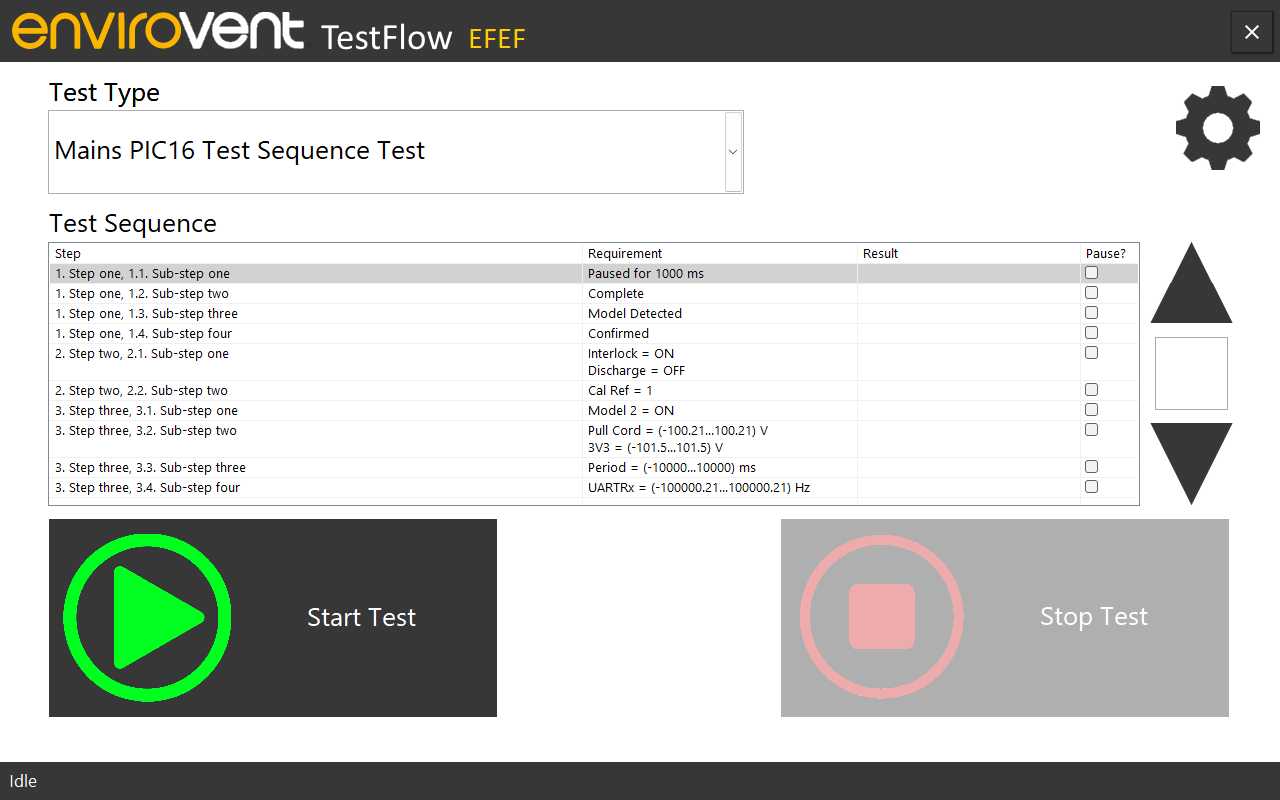

Each PCB has its own test sequence, see sample test execution screen below, defining the required tests to be performed along with test limits and other necessary parameters. The types of test steps that can be configured include:

- Digital/Analogue/Frequency/Period Inputs - measure values (voltage, current etc.)/states on the DUT and check they are within expected limits.

- Digital/Analogue Outputs - Set values/states of outputs to the DUT to induce behaviour to be checked in later steps.

- Operator Confirmation - If you do need a manual step, inform the operator and wait for their confirmation.

- Program - load a firmware file to the DUT.

The R&D Director of the business we were working with made this comment about working with Argenta, “Argenta were an ideal partner for our project. They developed a great solution that met our requirements, within the agreed budget. We look forward to working with them again”. If you think we can help you with your PCB test system, get in touch.

Back to Case Studies