iFCS project continues and things are starting to get interesting!

13 July 2017

We are now ¾ of the way through our collaborative R and D project with Greenbank, Drax and the University of Nottingham (UoN) and it’s getting to the stage where things start to get interesting!

In case you missed the last update, here’s a quick recap of the project objective. Using InnovateUK funding, we are looking to develop an Intelligent Flow Control System (IFCS) for Coal Fired Power Stations (CFPS). The system will be fully automated and will adjust to suit modulation in flow performance of mill, fuel types, quality, wear and load. It will provide flow feedback, allowing burners to achieve optimum stoichiometric conditions, thereby increasing plant flexibility and responding better to demand from the grid.

Over the last 6 months we have been working towards the demonstration of the prototype system on a test rig representing a scaled down power station mill to burner configuration, see image below. This has involved the UoN developing the control algorithm, Greenbank preparing the test rig and ourselves developing the software to bring the two together!

As we mentioned in the previous update, we were considering the use of NI VeriStand to deliver our objective. After some challenges along the way, we’ll cover these in a separate post, we did use VeriStand for the demo and it work really well. UoN developed their algorithm using Matlab, which we were able to convert into a Simulink model that could be imported and run in VeriStand. The obvious benefit to this is not having to translate the Matlab code into LabVIEW. Not having to do that meant we were quickly able to run updated algorithms and we could be 100% confident that we would be running the same code as was developed and tested in Matlab.

We used Custom Devices for a number of functions. Firstly to configure the system/model, reading in parameters from file. Secondly to receive data over Modbus from an external system and finally to enable data logging. Custom devices are created with LabVIEW using a VeriStand template library that includes interfaces to VeriStand data and timing resources. This gives custom devices the ability to behave as native tasks within the VeriStand Engine.

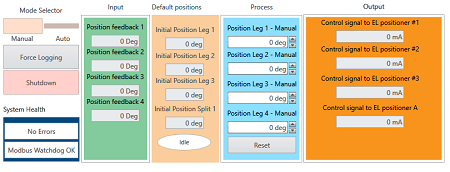

We also used VeriStand for the user interface, which had basic functionality to visualise outputs and control inputs to the test rig. Below is an example of one of the earlier user interfaces that was developed;

The great news is that the results from the demonstration have been accepted by Drax and we are now progressing the plant scale application. Well done to all partners!

If you’re interested in how we might be able to help solve your challenges, maybe with VeriStand, please get in touch.

Back to Blog listings