AMRC project on the right track!

08 June 2017

This post follows on from our previous blog, describing the project kick off of the delivery of an experiment execution system for the Advanced Manufacturing Research Centre. We’ve had interesting technical challenges along the way and we thought we’d share the solutions that we came up with. Here are three examples.

cRIO Saving Direct to SQL

One of the key elements of this project is the data collected from the LabVIEW data acquisition and analysis system running on the cRIO. The cRIO acquires data from the machine PLC and sensors on the machine to enable analysis to be performed. The results of this analysis and the acquired data from the machine PLC are saved to a SQL database.

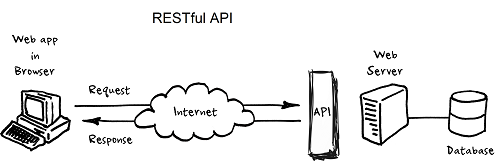

There are a number of ways we could have approached this, for example via a RESTful API or via a Windows host PC. Both of these examples require additional development on top of the LabVIEW code for the cRIO. We wanted to keep it as simple as possible and implemented a solution to write straight to the SQL database from the cRIO. This limited the development required and therefore the amount of code that needs maintaining.

We will be doing a blog post in the future about the details of this solution.

Interacting with Windchill via a Web Service

One of the key objectives we highlighted in the kick off post was to enable a paperless shop floor. This is predominantly achieved through the use of PTC’s Windchill, which is a product lifecycle management tool. Windchill is used to store all documents related to the experiments that are run on the machines and supports version control, document sign off and much more.

The element of our execution system that is accessed at the machine workstation enables the operator to select a project and access all related documents. In order for this to be possible, our system needs to communicate with Windchill to first of all retrieve the documents, then perform check out, download and finally check in when edits are complete. This is all done through the use of a Web Reference based on the Windchill Info Engine web service.

Again we will expand upon this in a future blog post as we learnt loads!

cRIO to MTConnect

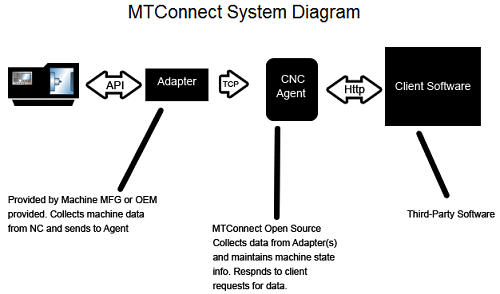

In the kick off blog post we also talked about utilising OPC UA to enable the communication with the machine PLC. Whether this is possible or not is reliant on the setup of the machine and whether OPC is a feature that has been integrated into a machine.

On the machines we have worked on to date, MTConnect has been the available connector. This is implemented by running the adapter on a PC located next to the machine, which, on request, publishes a standardised XML to the cRIO. This is then parsed into a usable form in the LabVIEW application to access the required parameters for the analysis and saving to the database.

We’ve had the opportunity to work with a combination of really interesting technologies and we are looking forward to bringing it all together in the coming months.

If you have any opportunities to improve your manufacturing environment, get in touch!

Back to Blog listings